Posted: 6 years ago

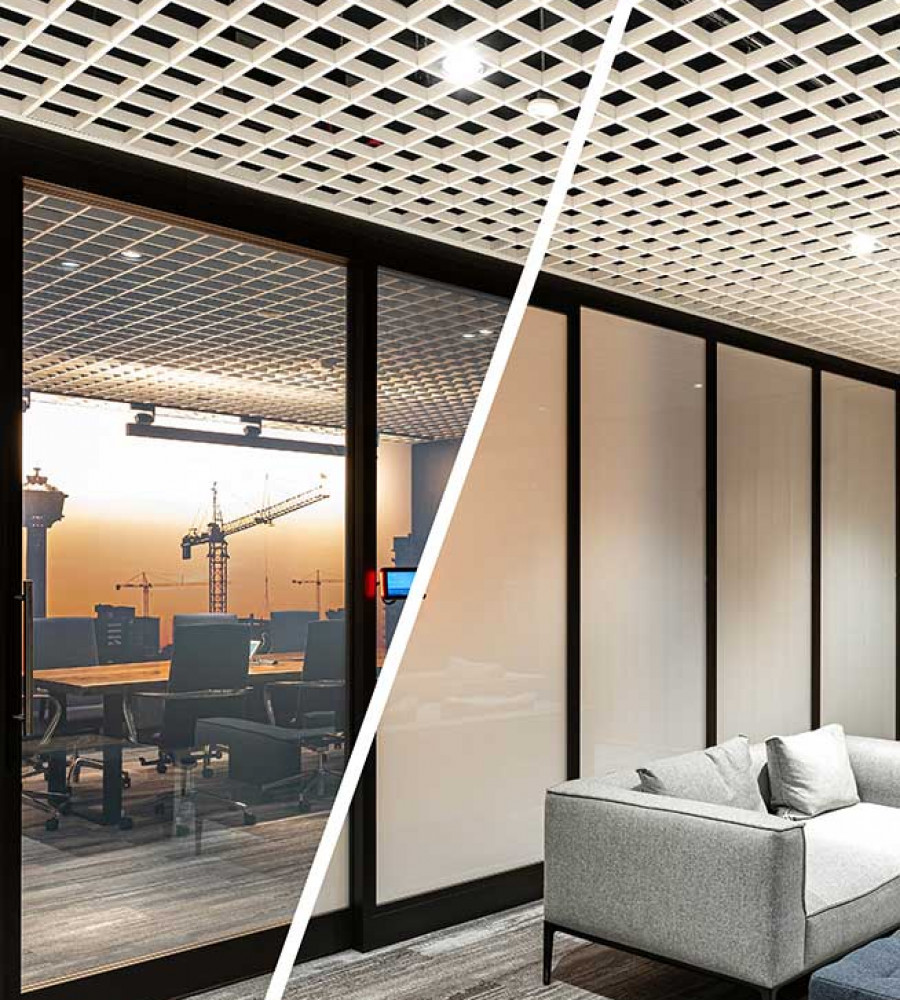

Spotlight on: Our Glass Cutter Craftsmen

At Goldray Glass, we are unique because many of our staff have been here for multiple generations. The personal bonds and professional respect that we have developed as a team is what makes for a productive work environment. Our glass cutter craftsmen are simply outstanding. They take pride in their contribution to get projects completed. Perfection and precision are vital traits that come together to get the glass to the requested sizes and shapes.

In our cutting department, a wrong cut can be shattering. As glass experts, our cutters know how crucial their role is, and their dedication to upholding our values is widely appreciated in the company. Cutting glass is a demanding and challenging process that requires attention to detail. We are pleased to showcase a few of the members of our trained cutting team.

Dawit has been the Team Leader for four years. He moved to Canada eight years ago from Eritrea, Africa, and has gained the respect of his colleagues for his seriousness about his floor responsibilities. He was swift to learn and knows where any piece of glass is in his department. When asked, he will simply walk right to it amidst the hundreds of types available. Besides his work, Dawit loves watching basketball and takes much ribbing that his favorite player is Lebron James.

Yonas is one of the technicians on the cutting team. Also born in Eritrea, he has worked in many different departments since joining the Goldray family. Yonas first started work in tempering as a glass handler and quickly worked his way up to become the furnace operator. He held that position for about six years until he moved over to learn about silk screening. On that team, Yonas took on the role of the lead hand for the next six years. Due to his interdepartmental experiences and as the backup cutting operator, he can anticipate potential challenges and advise the team accordingly. Yonas likes to get his hands dirty by fixing cars in his garage for friends and family, as well as working on home renovations around town. These are hands-on skills that the Plant Manager, Selwin, values on the plant floor.

Whether the architectural glass project includes one or several decorative applications, Selwin knows that, when a work order enters into the system, the cutting team is the first critical step in the process. The cutting work begins when full-size glass sheets are lined up and laid flat on the cutting table with all the relevant specifications programmed into the right machines. Innovation in automation is an area that our cutting team embraces as it supports their quest for accuracy and productivity.

Reduced product waste and maximum efficiency in the production line is the approach of the cutting team. The waste product is collected in a bin and taken away for recycling. At another location, the discarded glass is ground down and added to paint, where its reflective qualities are perfect for marking travel lanes. It might also be used in a process called dustless blasting that uses a mixture of water and an abrasive, such as recycled glass, to remove paint from cars.

Our team of cutters love to see how the designs turn out. This interest is a big part of the sense of satisfaction and accomplishment in the overall process of creating beautiful and breathtaking products. What else do the glass cutters love about being part of the Goldray family? The flexibility and warm culture are reasons that come up again and again. Selwin explains that it is easy to fit in as long as new team members are open, honest, and willing to look out for each other. The cutting team embraces Goldray’s values and helps us to continue with our commitment to creating the most excellent workplace culture.

To stay in touch with the Goldray Glass team, join us on LinkedIn, Instagram and Facebook where we regularly post project pictures and case studies as we build our community of industry professionals.